Core Services

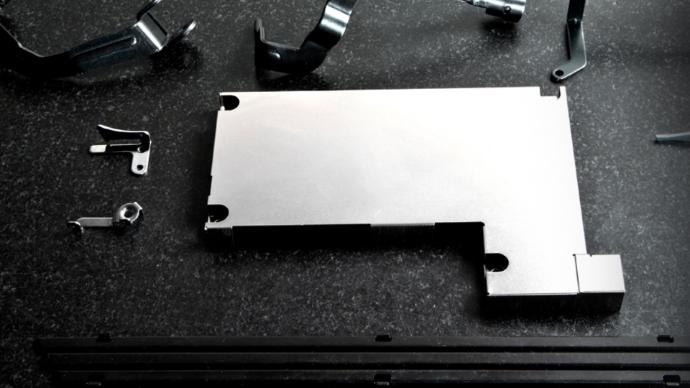

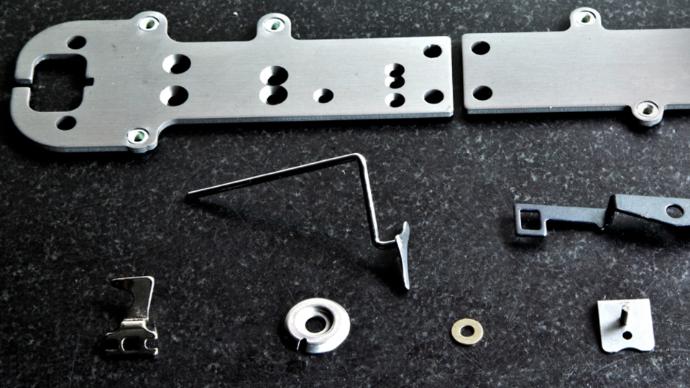

Stamping & Finishing Services

An Integrated Solution

HIROKI CO., LTD. is dedicated to providing a full-service solution, from stamping to post-processing, for our domestic and international clients. Our facility is equipped with a versatile range of automated presses (110T, 80T, 60T, 40T, 20T, and 15T) to accommodate diverse metal materials and product requirements. We offer flexible production capabilities, from sample prototyping and small-batch pilot runs to continuous mass production.

In addition to our core stamping expertise, we provide a complete suite of finishing services, including Precision Grinding, Deburring, Parts Assembly, Surface Finishing, and Tapping.

Precision Grinding

Achieving Ultimate Flatness and Dimensional Accuracy

1. Process Principles & Applications

Precision grinding is a machining process that uses a grinding wheel to meticulously abrade a workpiece's surface. Its primary goal is to enhance the flatness and dimensional accuracy of a component. This process is widely applied for surface finishing on precision parts such as molds, electronic device components, and inspection jigs.

2. Process Advantages

- Improved Surface Flatness: Eliminates surface unevenness, enhancing the quality of the product’s contact surfaces.

- Precise Thickness Control: Ideal for thin parts or components requiring tight thickness tolerances, ensuring uniformity.

- Corrects Heat Treatment Deformation: Grinding can remove deformation that may occur after metal heat treatment, ensuring the part remains flat and stable.

- Reduced Machining Stress: Fine surface finishing reduces residual stress on the part, extending its service life and durability.

3. HIROKI's Professional Capabilities

HIROKI is equipped with a vertical-spindle surface grinding machine capable of large-area grinding, meeting stringent demands for flatness and dimensional accuracy. Our grinding technology is suitable for various metal materials, including steel, stainless steel, and aluminum alloys. We also provide customized grinding solutions to meet our clients' specific needs.

Read More

Deburring

Enhancing Product Safety and Appearance

1. Causes and Impacts of Burrs

Burrs are a common defect in metalworking, typically appearing after cutting, stamping, or drilling processes. Burrs not only affect a product’s appearance but can also complicate assembly, reduce performance, and even pose a safety risk to the user.

2. Deburring Techniques

- Manual Deburring: Uses tools like files and sandpaper for manual finishing, suitable for small batches or complex-shaped parts.

- Mechanical Deburring: Employs specialized equipment for high-volume processing, improving efficiency and consistency.

- Electrolytic Deburring: Removes burrs from metal parts through an electrolytic process, ideal for precision components.

3. HIROKI's Professional Capabilities

HIROKI utilizes various advanced deburring equipment, allowing us to select the most suitable method for different materials and part geometries. Our deburring services not only enhance a product's aesthetic quality but also ensure its safety and functionality.

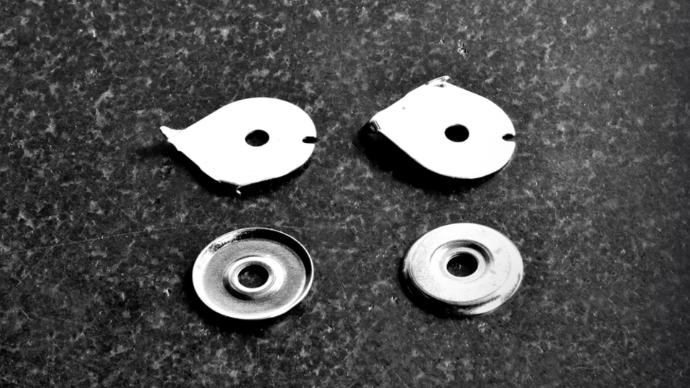

Rivet Processing

Our punching and riveting processing service utilizes the pressure capabilities of a punch press, combined with precisely designed tooling, to perform various types of riveting operations. Our services include: integrated punching and riveting, press-fit riveting, self-piercing riveting, and customized rivet tooling development.

Read More

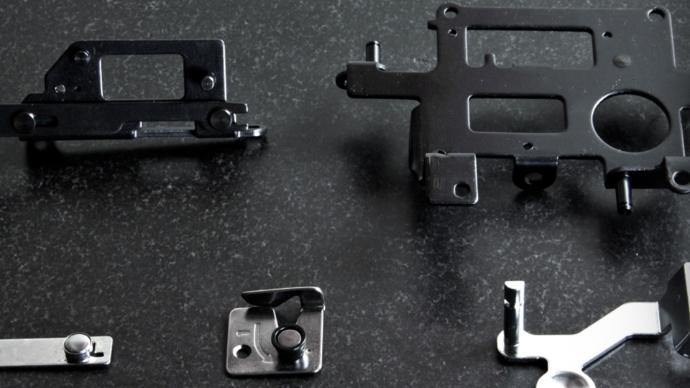

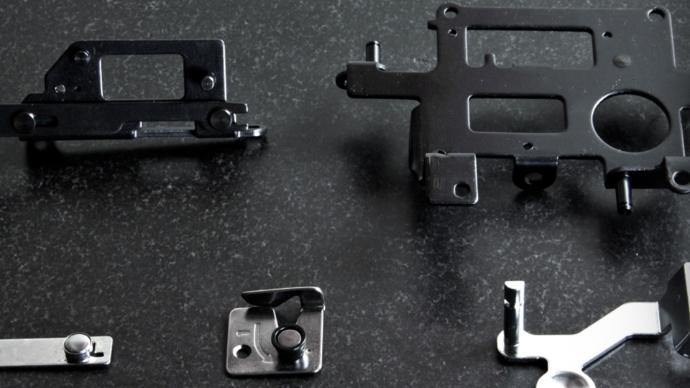

Parts Assembly

Achieving Efficient Integration and Functional Optimization

1. The Importance of Assembly

Parts assembly is a critical step that combines individual processed components into a finished product. It directly impacts the product’s performance, quality, and lifespan.

2. Assembly Techniques

- Mechanical Assembly: Uses fasteners like screws and nuts, suitable for products that need to be disassembled.

- Welded Assembly: Joins parts permanently through welding, ideal for products requiring high structural stability.

- Adhesive Assembly: Uses adhesives for joining, suitable for certain special materials or structures.

3. HIROKI's Professional Capabilities

HIROKI provides comprehensive, one-stop parts assembly services. By managing the entire process from component manufacturing to final assembly, we ensure quality and efficiency at every stage. Our experienced assembly team can provide tailored solutions to optimize product function and control costs based on your specific needs

Read More

Surface Finishing

Boosting Product Durability and Aesthetics

1. The Purpose of Surface Finishing

Surface finishing is the process of treating the surface of a metal part to enhance its properties, such as corrosion resistance, wear resistance, and appearance, thereby extending its service life.

2. Common Surface Finishing Methods

- Electroplating: Applies a thin layer of metal (e.g., chrome, nickel) to a surface, enhancing its corrosion resistance and appearance.

- Anodizing: Primarily for aluminum and its alloys, this electrolytic process forms a protective oxide film on the surface, improving corrosion resistance and hardness.

- Powder Coating/Painting: Applies a protective and decorative coating to the metal surface.

3. HIROKI's Professional Capabilities HIROKI offers a variety of surface finishing services and can select the most suitable method based on a product’s specific characteristics and client requirements. Our surface finishing expertise not only improves product performance but also strengthens its market competitiveness.

Tapping

Ensuring Precision Connections and Structural Stability

1. Definition and Application of Tapping

Tapping is the process of cutting internal threads into a metal part, commonly used for components that require screw connections. Precise tapping ensures a tight connection between parts, improving a product’s structural stability and lifespan.

2. Tapping Techniques

- Manual Tapping: Suitable for small batches or components with complex shapes.

- Mechanical Tapping: Uses a tapping machine for batch processing, improving efficiency and consistency.

- CNC Tapping: Achieves high-precision tapping using a CNC machine, suitable for parts with strict accuracy requirements.

3. HIROKI's Professional Capabilities

HIROKI is equipped with advanced tapping machinery to perform thread cutting of various sizes and specifications. Our tapping techniques guarantee the precision and consistency of threads. We can also provide customized tapping solutions to meet specific client needs.

Read More

3D Printing

Hongji is equipped with advanced tapping equipment capable of processing threads of various sizes and specifications. Our tapping technology not only ensures thread accuracy and consistency, but also allows us to provide customized tapping solutions based on customer needs.

Read More

Coping Saw Blade

We provide high-quality, durable, and high-performance saw blades. Precision-engineered from premium materials, our products combine years of industry expertise with innovative R&D to continually enhance durability and cutting efficiency.

Read More