3D Printing

Hongji positions 3D printing as a key auxiliary technology for accelerating development, optimizing manufacturing processes, and realizing complex designs.

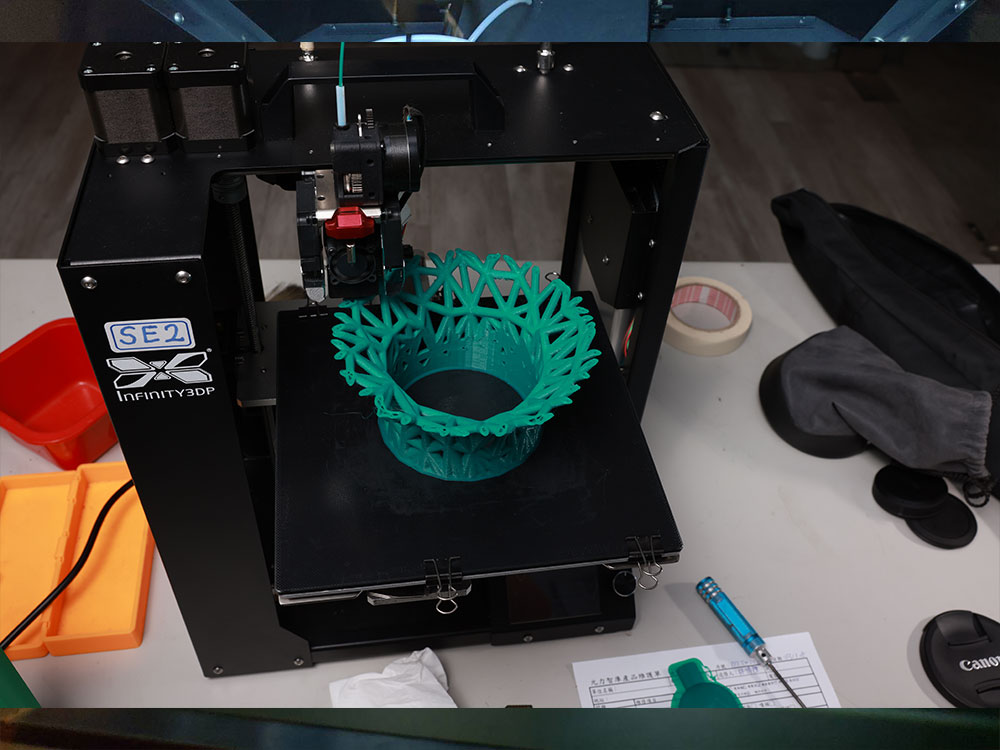

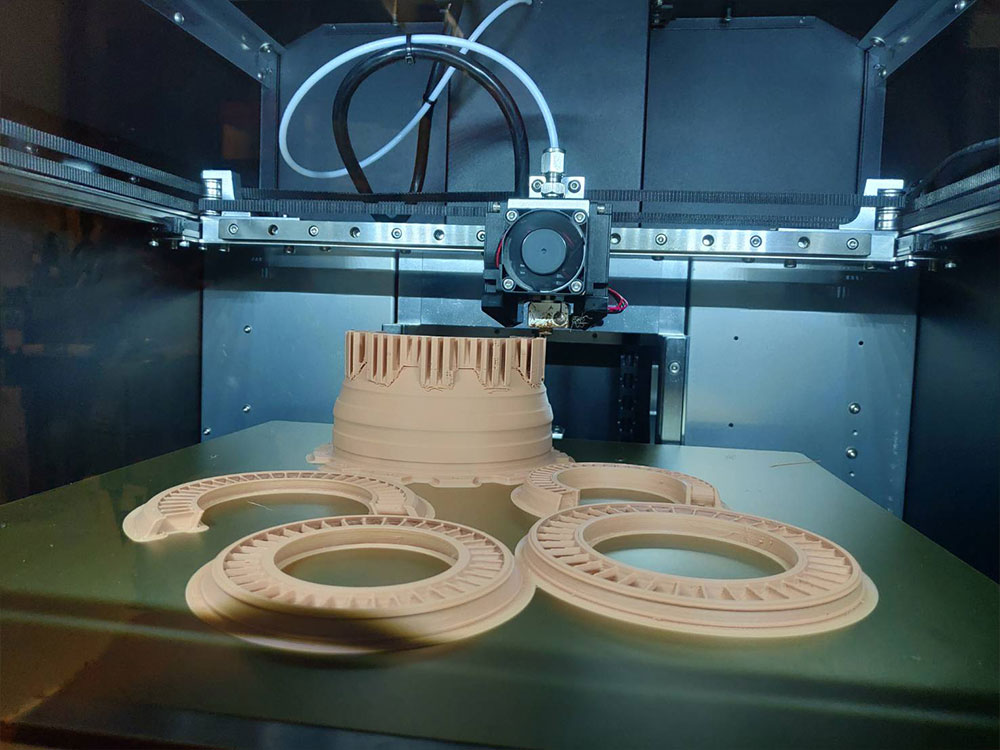

To this end, Hongji has introduced the industry's most advanced FDM (fused deposition modeling) equipment—the infinity3dp X2 Pro high-speed 3D printer—and strategically integrated it into our core punching service workflow, providing unprecedented value to our customers.

Our services focus on three key areas:

Rapid Prototyping and Design Verification

Before you invest in expensive stamping dies, we can leverage the high-speed performance of the infinity3dp X2 Pro to produce physical models that are virtually identical to your design in a fraction of the time.

Services:

Appearance and Mechanical Verification: Using our X2 Pro, we can quickly print dimensionally accurate models (using materials like PLA and PETG) using FDM technology, allowing you to physically touch and evaluate the product's appearance, feel, and mechanical fit during the design phase. Functional Prototypes: Leveraging the X2 Pro's diverse material support, we can create prototypes with the required strength and toughness using engineering-grade plastics such as ABS and high-toughness nylon for initial functional testing.

Customer Value:

Significantly Reduce Development Cycles: The X2 Pro's high speed means prototyping time is reduced from days to hours, enabling faster design iterations.Reduced Development Risk: Identify design flaws before mold creation, avoiding costly mold modifications and time delays.

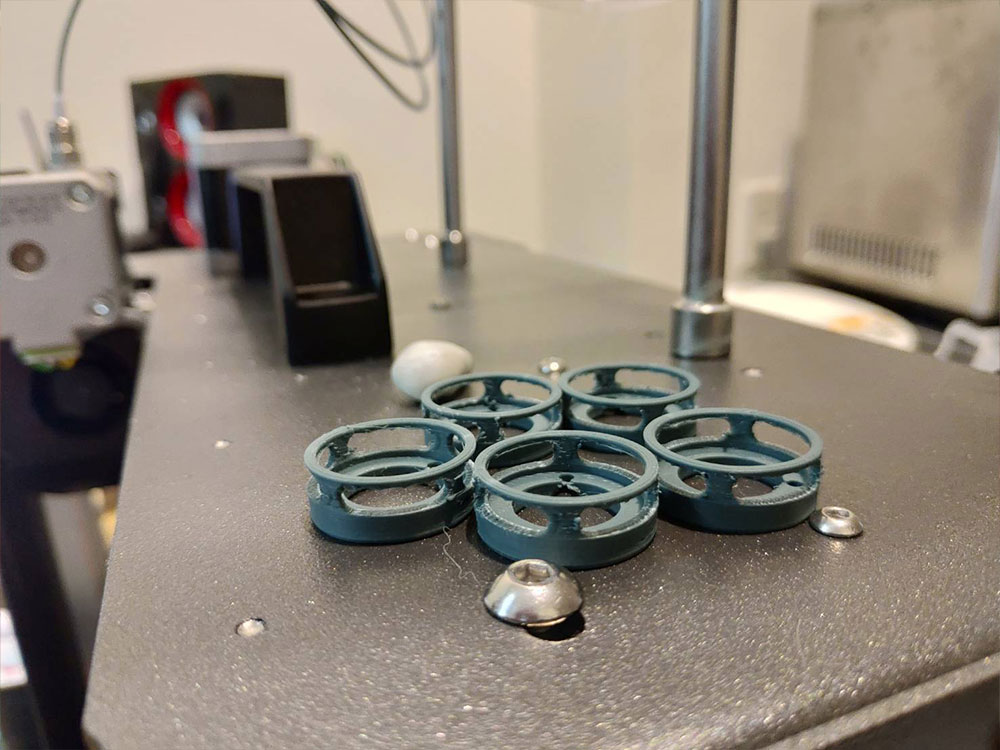

Innovation in Process Assistance Tools

This is the most cost-effective application of 3D printing in the stamping process.We utilize the infinity3dp X2 Pro high-speed 3D printer and select high-strength engineering-grade materials such as nylon and carbon fiber composite (PA-CF) to customize high-precision auxiliary tools for production lines.

Services:

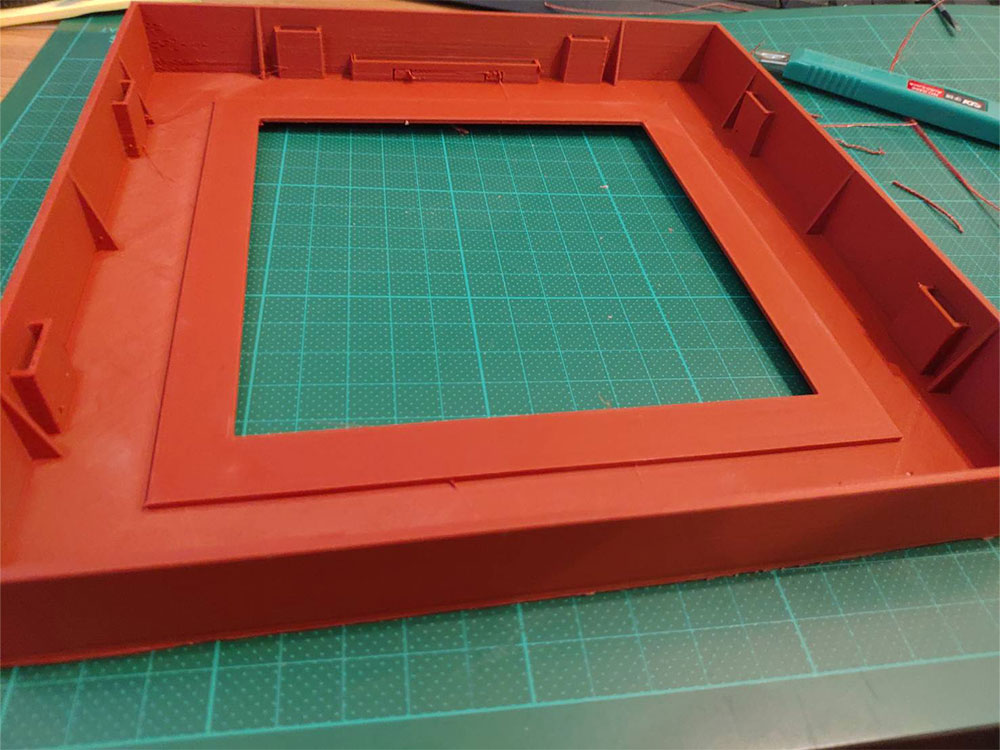

Inspection Gauges: Customize high-precision 3D-printed inspection gauges for stamped parts. Operators can quickly place parts on the inspection jig and efficiently determine whether their dimensions, contours, or hole positions meet tolerances.

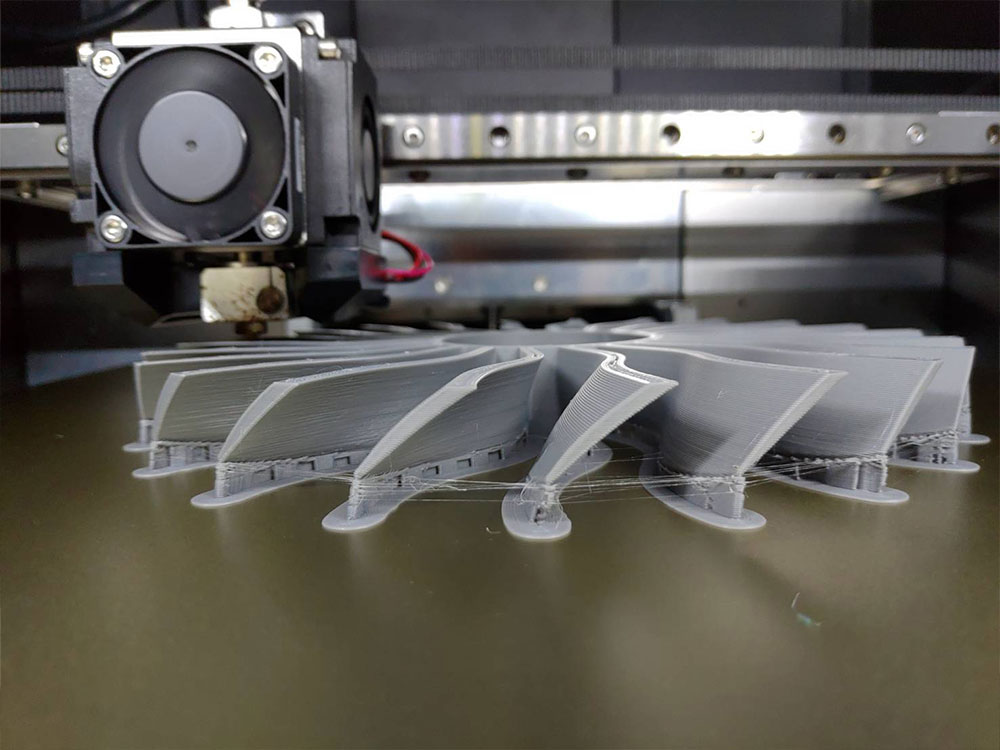

Assembly Jigs: When stamped parts need to be assembled, customized 3D-printed jigs securely position the parts and ensure assembly accuracy. Their high speed allows us to print new parts the same day if a jig is damaged or a design change occurs, minimizing production line downtime.Soft Tooling: For small-batch trials, we use 3D-printed dies made of high-strength composite materials, combined with a punch press, to perform small amounts of sheet metal bending or shallow drawing to verify the mold design.

Customer Value:

Ultimate Customization and Response Speed: Custom jigs can be created and iterated within hours, perfectly meeting the immediate needs of the production line.

Improved Quality Consistency: Precise inspection jigs and fixtures effectively reduce errors caused by human inspection and assembly.

High Strength and Durability: Tools printed from composite materials such as carbon fiber are designed to withstand the rigors of factory environments.

Integrated Manufacturing of Composite Parts

This service combines the advantages of stamping and 3D printing to create high-performance composite parts that cannot be achieved through a single process.

Service Details:

Metal Frame + Plastic Shell: We first mass-produce a high-strength and precise metal frame or base using a stamping press. We then use the infinity3dp X2 Pro to create a lightweight, ergonomic plastic shell (using elastic materials such as TPU) with complex snap-on features.

Stamped Part Customization Enhancement: Customized mounting brackets, nameplates, or additional functional modules can be 3D printed onto standardized stamped parts for specific customers.

Customer Value:

Strength and Design Freedom: Perfectly combines the rigidity of stamped metal with the lightweight and customizable appearance of 3D printing.

Simplified Supply Chain: Hongji provides integrated manufacturing and assembly for stamping and 3D printing.

High-Value-Added Products: Ideal for industries such as aerospace, high-end hand tools, medical assistive devices, and customized mechanical equipment.

Service Application Comparison Table

|

Application Areas |

Services Provided by HIROKI |

Value Created for You |

|

Early Product Development |

Use the infinity3dp X2 Pro to print prototypes for appearance and mechanical verification. |

Reduce risk and accelerate time to market: Ensure design accuracy before mold creation. |

|

Mold Development and Pilot Production |

3D print pilot production soft molds for small-batch molding testing. |

Cost-Effectiveness: Validate mold design at a low cost, avoiding costly modifications. |

|

Mass Production Quality Control |

Use the X2 Pro to customize high-strength composite inspection fixtures. |

Improve quality and efficiency: Achieve fast and accurate quality inspection. |

|

Part Assembly Process |

High-speed printing of dedicated assembly and positioning fixtures, with same-day replacement. |

Stable and reliable, uninterrupted production: Ensure assembly accuracy and production flexibility. |

|

High-End Composite Products |

Combining stamped metal parts with FDM 3D-printed plastic parts into a single part. |

Maximized performance: balancing strength, lightweight and complex functional design. |

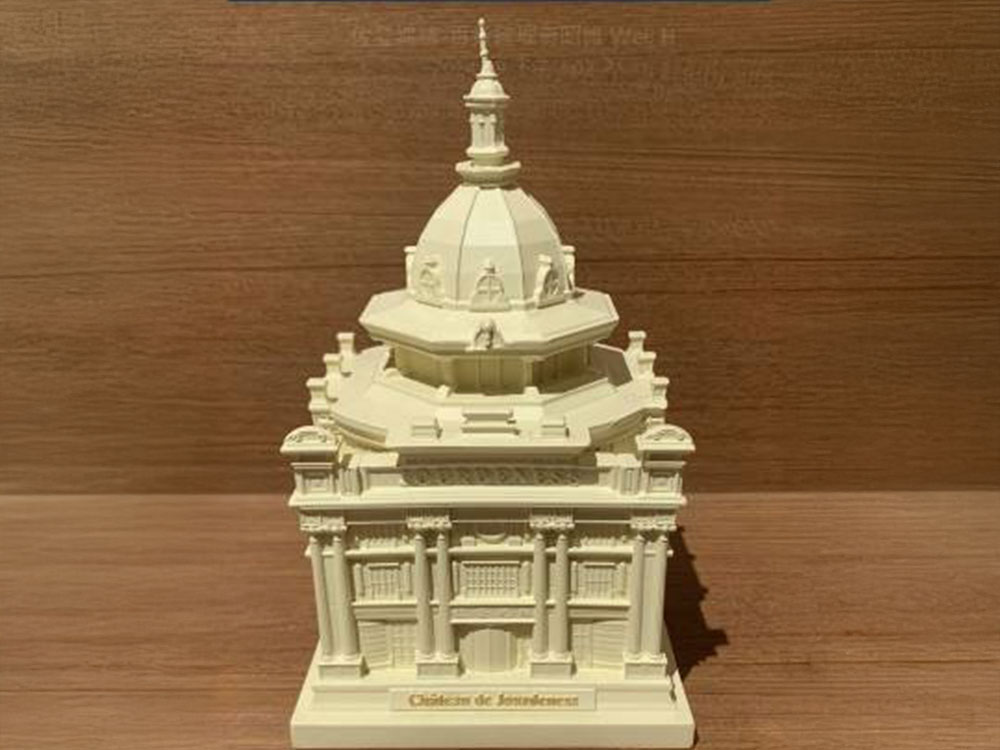

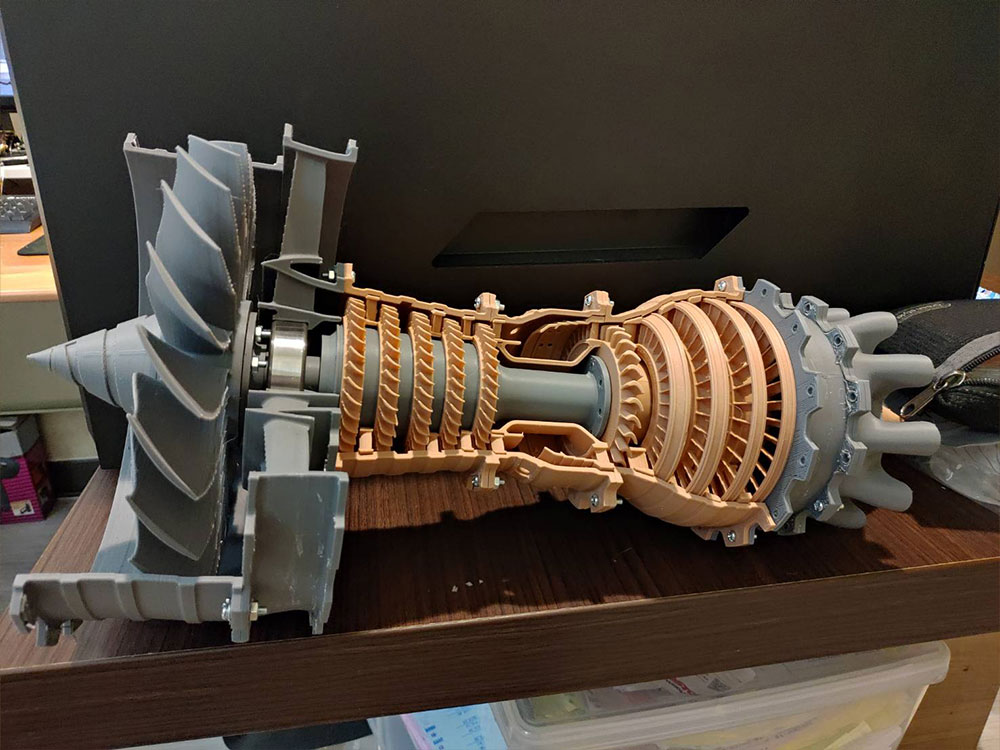

3D Printing Case

Summary

HIROKI Co., Ltd.'s investment in the Infinity3dp X2 Pro High-Speed Edition demonstrates our commitment to putting innovative technologies into practice. We not only possess a deep foundation in traditional manufacturing, but also actively embrace advanced tools like FDM additive manufacturing, turning them into Swiss Army knives, flexibly applying them to every step of the stamping process to maximize efficiency for our clients' projects.

If you're looking for a manufacturing partner who not only understands metalworking but also integrates innovative technologies,

please contact us to discuss how we can make your products even more competitive.